Cold Process Soap Lye Water Solution Coloring Pages

Additive and scent at light trace. Beige to beige with dark specks if the leaves are left in - Infuse leaves in waterlye solution.

Cold Process Soap Making Tutorial

Melt and pour soap can be used with low and high pH colors.

Cold process soap lye water solution coloring pages. Adding lye to water causes a exothermic reaction that causes the lye water to reach temperatures up to 200. Soap reaches trace when it thickens sufficiently that you can see ripples across the top of the soap. Beginner video showing how I mix lye in water for soap making.

This link will take you to a great list of our pigments and below you will see some of our best lightweight oils for mixing colorants. Chocolate brown - Add at trace andor to lye solution. Slowly pour the lye water into the oil.

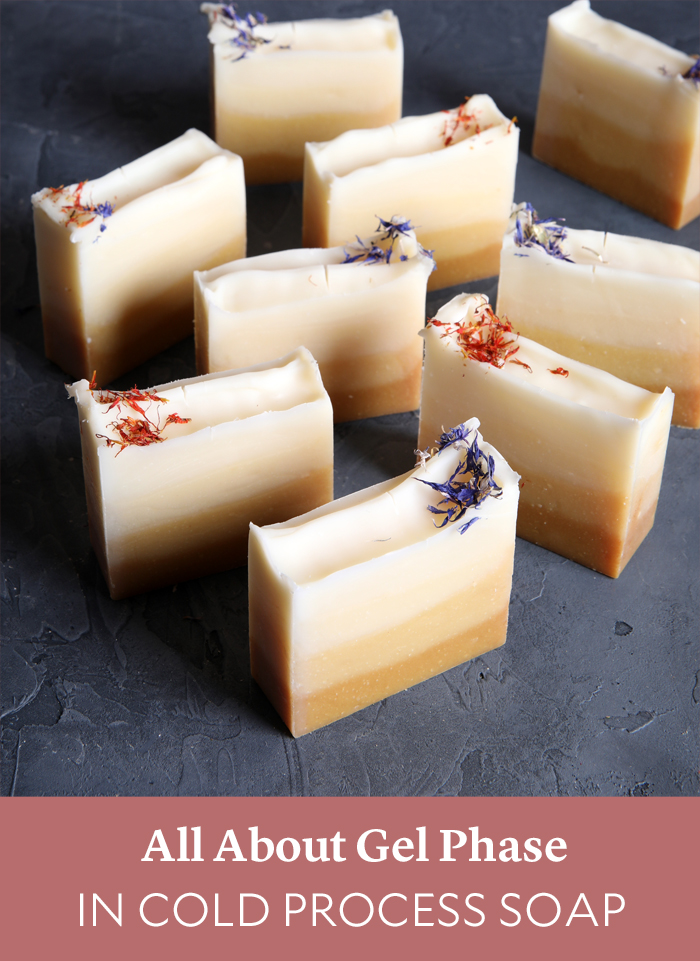

Fats oils and butters. It will give your soap a lovely rustic look as seen in the Espresso Shot Cold Process Tutorial. The most water in.

Blend with stick blender until soap traces. Pros of water discounting. A cold process soap making tutorial with a complete explanation and demonstration of how to masterbatch lye and oils for cold process soap making.

Typically a recipe uses about 22 liquid. Both use different lye temperatures and each works equally well. LabColors do bleed.

These molds behave similarly to silicone molds but are even worse at holding onto cold process soap. Because the lye solution becomes so hot it needs time to cool for soaping. The Layered Lavender Cold Process Soap Tutorial gets its lovely hue from Periwinkle High pH LabColor.

Be careful not to splash the lye water. I personally add the pigment dry in a scoop on top of the surface. Use sodium lactate or salt in the lye solution a water discount and a high amount of solid fats.

A water discount as little as 15 times the lye bringing to trace pretty fast and then adding hydrosol to make up the remaining water quantity after trace. Lye Water Solution. N If you are making a swirled soap you can add each color to thinly traced soap.

Sep 07 2016 In cold process soap add the grounds at trace and whisk gently to combine. Jul 22 2015 Just like soaping oils a great lye temperature for soaping is 120-130. Combining Lye Water and Oil Insert your stick blender into oil mixture.

Click here for cold process soap making recipe directions. Stir the water well to make sure the sugar or salt is completely dissolved and then move on to adding the lye to the water. Too low and the soap may take forever to trace or could sieze quickly this depends on the oils used in the recipe.

Nov 11 2015 High pH LabColors are used for cold process soap. Dec 04 2013 Learn to Prepare Colorants for Cold Process Soapmaking from Soap Queen on Vimeo. The wrong temperature of the lye can have adverse effects.

Olive leaf powder Olea europaea. Even then clear plastic molds arent always reliable. Red Moroccan Clay Red Kaolin Clay.

Check out the amazing amethyst color from Easter Purple High pH LabColor in the How to Make Soap Gems video on Soap Queen TV. For more information on coloring your soap. Slowly add the lye.

For instructions on soap making visit my pages describing the Cold Process and Room Temperature methods. Warm brown - Add at trace. As the soap cures the water evaporates and creates harder longer-lasting bars.

Add the Lye to the Water. You can also add tea leaves or ground tea to your melt and pour and cold process soap. I then place my stick blender right on top of the scoop of colorant push down and pulse quickly.

If your recipe calls for adding sugar or salt to the lye water solution add it to the water before you add the lye. Weigh the Lye for the Lye Solution. 100 Olive Oil Soap also know as Castile Soap INGREDIENTS.

Coffee grounds add exfoliation and interest to the Espresso Shot Cold Process Soap. Sugar or salt optional if your recipe calls for it METHOD. Nov 23 2020 Color.

28 rows Lye Conc WaterLye Ratio. Dissolving lye in hydrosols reduces the scent to the point that by the time the cold process soap is ready it is almost unscented. Water is used to dissolve sodium hydroxide lye so it can react with the oils and start the saponification process.

If you have suggestions for improvement or more warnings that need to be added please comment. To the oils before pouring in the lye solution. 77 grams lye sodium hydroxide 228 grams distilled water Please note this recipe will make a soap with very little bubbles.

Use 12 tsp to 15tsp per pound of soaping oils to get a chocolately. You can discount that to make a more concentrated lye solution. Weigh the amount of distilled water called for in your soap recipe.

I have learned to do the obvious. 600 grams olive oil. We also have a battery powered 4-in-1 Mini Mixer that will make the job fast and easy.

Techniques Archives Soap Queen

Techniques Archives Soap Queen

Milk And Honey Soap Cold Process Vs Hot Process

Milk And Honey Soap Cold Process Vs Hot Process

Cold Process Peppermint Soap Recipe Instructions Lovely Greens Recipe Peppermint Soap Soap Recipes Soap Making

Cold Process Peppermint Soap Recipe Instructions Lovely Greens Recipe Peppermint Soap Soap Recipes Soap Making

Natural Soap Making For Beginners How To Make Cold Process Soap

Natural Soap Making For Beginners How To Make Cold Process Soap

Pure Honey Cold Process Soap Tutorial Soap Queen Recipe Honey Soap Recipe Homemade Soap Recipes Soap Recipes

Pure Honey Cold Process Soap Tutorial Soap Queen Recipe Honey Soap Recipe Homemade Soap Recipes Soap Recipes

How To Make Soap From Scratch The Ultimate Guide For Beginners

How To Make Soap From Scratch The Ultimate Guide For Beginners

Bramble Beer Soap Soap Queen Beer Soap Cold Process Soap Recipes Soap Recipes

Bramble Beer Soap Soap Queen Beer Soap Cold Process Soap Recipes Soap Recipes

The Dreaded Undissolved Lye Ring In Soap Making Mixing Your Lye Solution Natural Soap Colorants Cold Process Soap Soap Making

The Dreaded Undissolved Lye Ring In Soap Making Mixing Your Lye Solution Natural Soap Colorants Cold Process Soap Soap Making

Troubleshooting Lye Heavy Soap Soap Queen

Pouring Lye Solution Into Oils Soap Recipes Peppermint Soap Soap Making

Pouring Lye Solution Into Oils Soap Recipes Peppermint Soap Soap Making

What S Wrong With My Soap Handmade Soap Recipes Soap Recipes Cold Process Soap

What S Wrong With My Soap Handmade Soap Recipes Soap Recipes Cold Process Soap

How To Make Lye Soap The Old Fashioned Way Frugally Sustainable

How To Make Lye Soap The Old Fashioned Way Frugally Sustainable

How To Add Lye To Milk For Cold Process Soap Soap Queen

Cold Process All Natural Handmade Soap

Cold Process All Natural Handmade Soap

Top 10 Free Printable Volcano Coloring Pages Online Coloring Pages Volcano Clipart Monster Coloring Pages

Top 10 Free Printable Volcano Coloring Pages Online Coloring Pages Volcano Clipart Monster Coloring Pages

Back To Basics Simple Gentle Cold Process Soap Soap Queen

Cold Process Soap Making For Beginners Tifforelie

Cold Process Soap Making Tutorial